Times E-PARK - New trends in urban complex building facades

Facade PRO means PROFESSION (professional) and PROGRESS (progress). It selects high-quality innovative curtain wall projects across the country every year, shares new technologies and new materials, promotes the diversified practice and development of building skins, and helps young curtain wall designers grow.

Guests of this issue

Liu Xiaokui, General Manager of TEC Architectural Technology Co., Ltd

"How to achieve low cost and high quality is one of the core challenges of being a curtain wall consultant."

Times E-PARK

Plug-in composite boutique urban complex

The total construction area of Times E-PARK is approximately 210,000 square meters, of which the second phase has a total construction area of approximately 100,000 square meters, including three commercial office buildings totaling 70,000 square meters, 27,000 square meters of boutique community commerce, and a 4,000 square meter outdoor garden for social gathering.

The architectural design concept is: based on the first phase of the office park, expand the plug-in type composite boutique urban complex, striving to use a rich architectural vocabulary to vividly demonstrate the contemporary Guangzhou city that integrates modernity and tradition, city and village, humanities and nature. image and renewed community status.

The design is based on the cultural context, based on the spatial function of the composite form, using the rhythmic and rich facade as the modeling technique, and featuring the "wedge-type" community commercial cultural form, successfully creating a "plug-in" for the city.

It is also like a filter of contemporary trends, an architectural montage that combines virtuality and reality, reflecting the rapid integration and transformation of urban and rural areas in Guangzhou in recent years, and the urban development process in which diversity and vitality coexist.

High-quality facades add architectural value

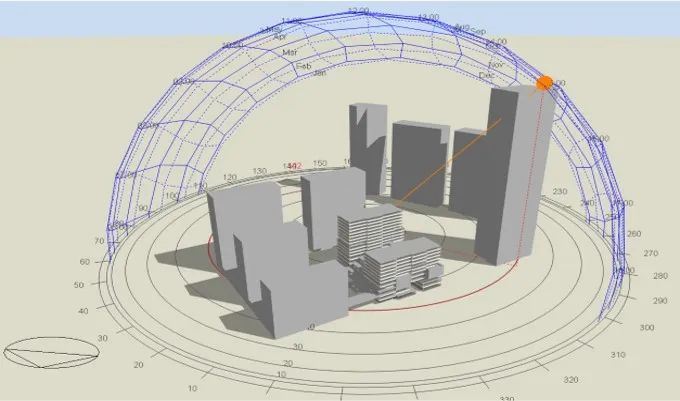

Building physical performance analysis + fifth facade design

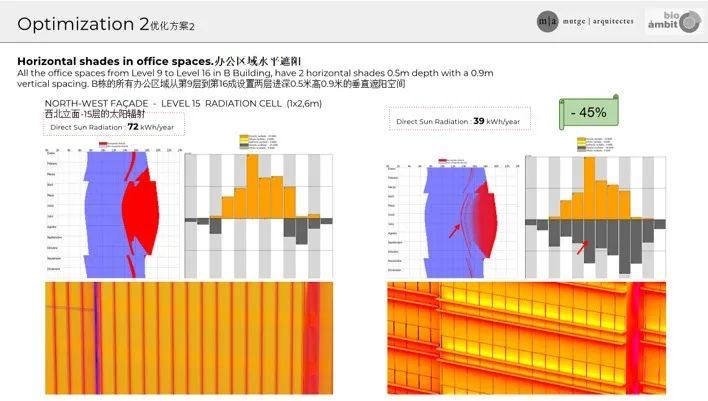

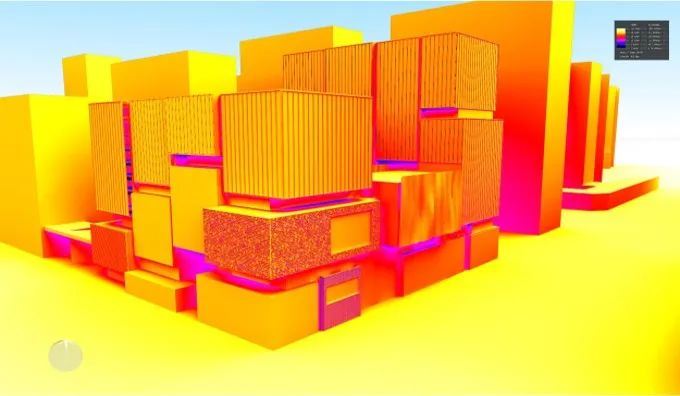

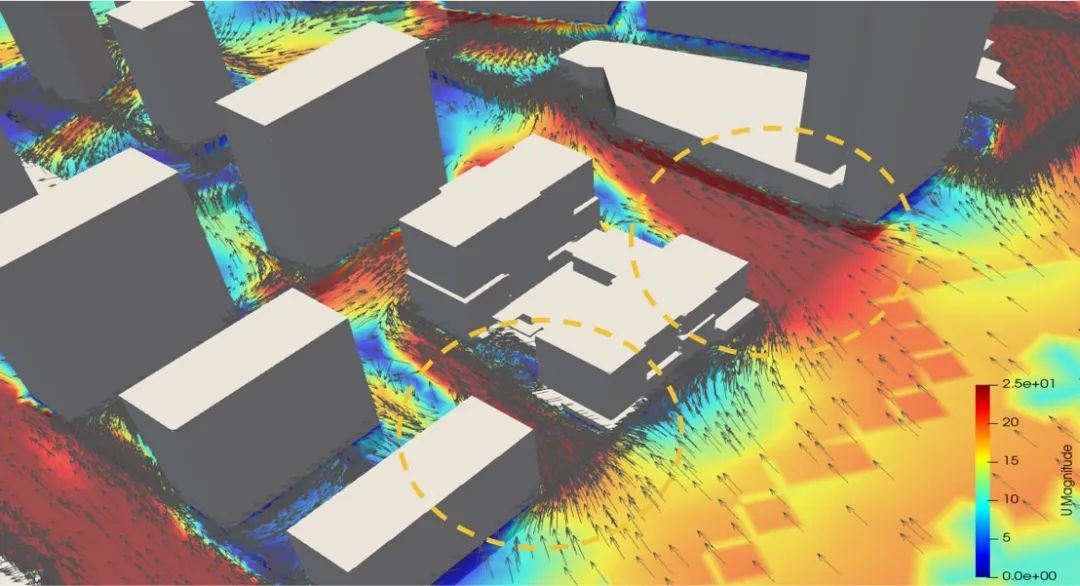

Building physical performance analysis

In response to the sustainable design needs of the project, we teamed up with a number of international green building consultants to collaborate on the project to formulate quantitative design indicators for physical performance targets, which were used to improve the quality of the project and the performance of each curtain wall system.

Analysis conclusions:

1. By using glass with high visible light transmittance, the annual solar radiation heat energy obtained through the windows can be increased by 2-3 times compared with the existing building plan.

2. The use of glass solutions with high visible light transmittance is the main solution to reduce annual lighting load.

3. The model solution of adding an adiabatic heat recovery system is a solution that mainly reduces the annual cooling load.

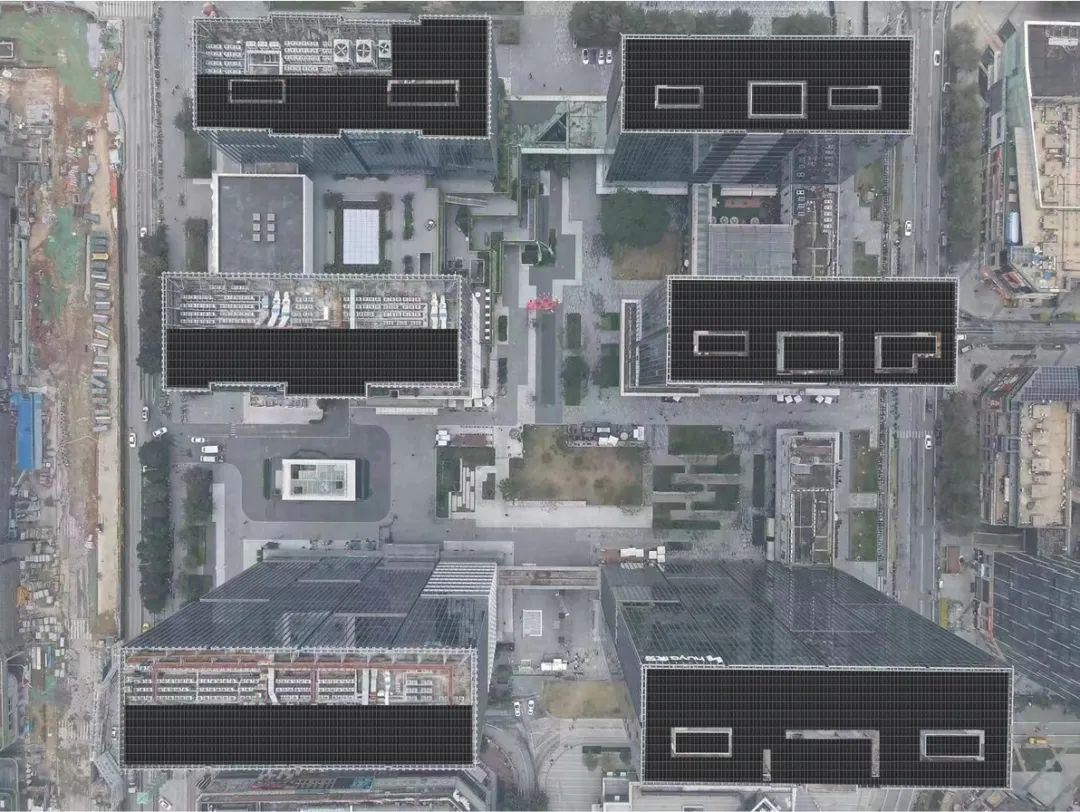

Fifth facade photovoltaic panel design

Through the design and use of the fifth facade roof, the building can be improved including: energy conversion, energy saving and emission reduction, reducing indoor temperature, improving the aesthetics of the building and increasing the value of the building.

Its role is mainly reflected in the following aspects:

1. Energy conversion and supply: Photovoltaic panels can utilize solar energy and convert light energy into electrical energy through the photoelectric effect. This electricity can be used directly by buildings, reducing reliance on the traditional grid and thus lowering energy costs.

2.Energy saving and emission reduction: The use of photovoltaic panels can reduce dependence on fossil fuels, thereby reducing greenhouse gas emissions, such as carbon dioxide, and helping to alleviate the problem of global climate warming.

3.Reduce indoor temperature: Photovoltaic panels installed on the roof can effectively reflect and absorb solar radiation, thereby lowering the indoor temperature, reducing the use of refrigeration equipment such as air conditioners, and further saving energy.

4.Improve the aesthetics of the building: Photovoltaic panels can be used as part of the building and combined with the architectural design to improve the aesthetics of the building.

5.Increase building value: Installing photovoltaic panels can improve the energy efficiency of a building and increase its market value. At the same time, for some areas encouraged by policies, the installation of photovoltaic panels can also enjoy government subsidies or tax benefits.

Diversified materials and facade forms

10+ curtain wall system applications

Podium frame mosaic glass curtain wall system

Main control factors and design strategies for the implementation of the plan:

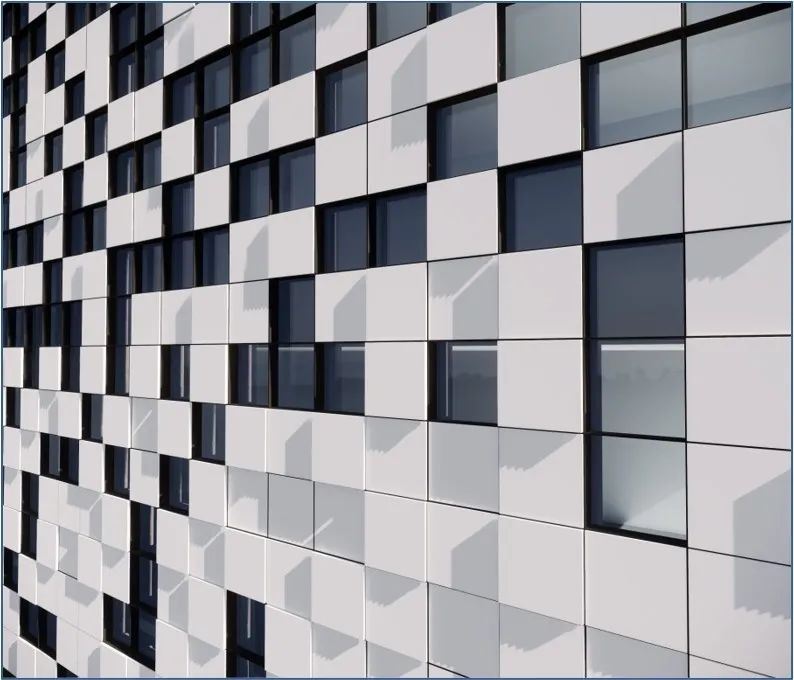

Deepening of the facade plan

Digital design (BIM) is used to accurately realize the architectural plan, and the parametric distribution of exterior decorative panels is used to express the facade design texture.

Selection of materials

frame-type glass curtain wall, exterior decoration aluminum alloy panels and components.

Appearance quality control

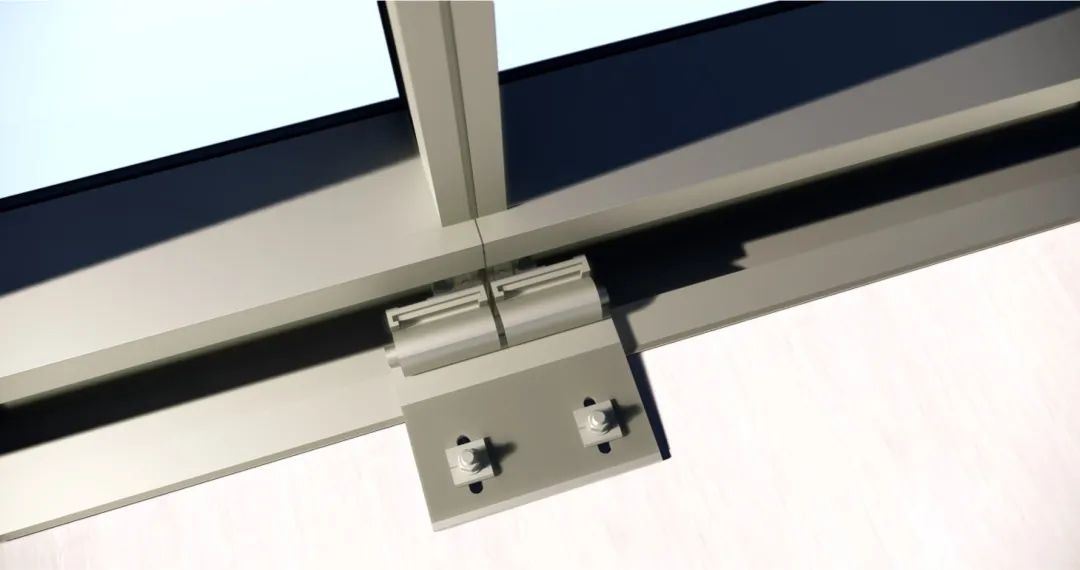

1.Outdoor exterior: The curtain wall and external mosaic aluminum alloy components adopt modular unit design and multi-level adjustment connection mechanism design to achieve precise control of the visual effects of the architectural plan.

2.Indoor surface: The reserved conditions for the intersection of curtain wall design and indoor fine decoration to verify and adjust the indoor visibility effect.

3.BIM technology investment in solution verification and VMU design stage.

4. Multi-level quality review of VMU visual models, model sections, regional tours, etc.

Technical configuration

Viewing area position: 8 (LOW-E) + 12A + 8mm ultra-white tempered insulating glass

Window wall position: 6 (LOW-E ) + 12A + 6mm ultra-white tempered insulating glass + 2mm aluminum back plate (fluorocarbon Spraying)

Inner glass: 12mm single piece of full-color glazed tempered glass

Exterior lattice panel configuration: 2.5mm white aluminum veneer (fluorocarbon spraying, three coatings and two baking), standard specifications: width 675mm×height 675mm

Stress-bearing components: aluminum profile (6063-T6), galvanized steel adapter (Q235)

Podium frame glass curtain wall system (with decorative aluminum components outside the partition window)

Main control factors and design strategies for project implementation:

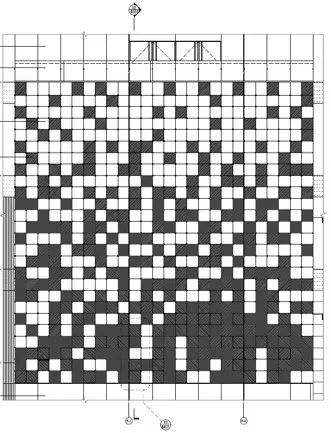

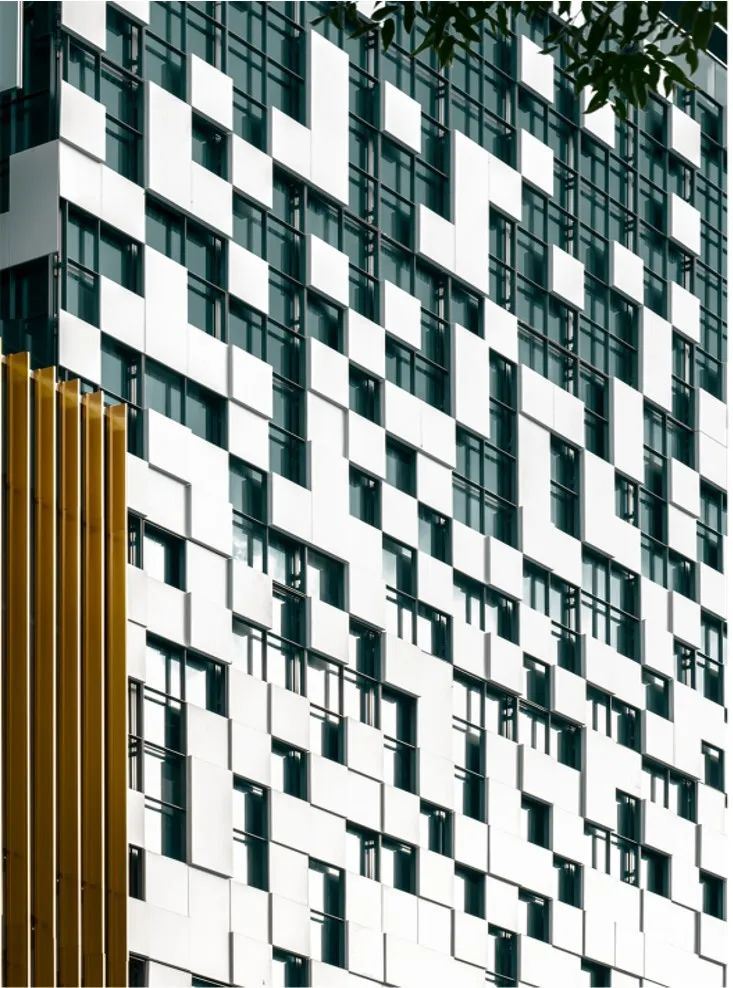

Deepening of the facade plan

The facade is close to Exit G of Hanxi Changlong Subway Station and is the first impression of the mall for subway commuters. At the same time, in order to increase advertising effectiveness, the system integrates large-area LED screen advertisements. Its design focuses on accurately realizing parameters. The visual impact brought by changing the window grille openings, so our company conducted a key parametric design study on the aluminum window grille components of the curtain wall.

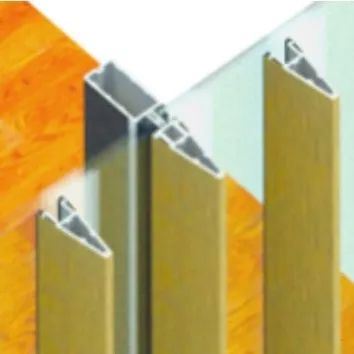

Selection of materials

The system solution is designed to be a glass curtain wall with a hidden frame with point clamps on the inner layer, and a customized aluminum alloy parametric decorative grate component on the outer layer.

Appearance quality control

1.Outdoor exterior: Accurately restore the architectural design intent and realize the gradient effect of the parameters of the openings of the aluminum window grille components.

2.Interior: Optimize the connection of the supporting steel structure system to meet structural safety while saving materials as much as possible. And use ultra-white high-transparency glass to enhance visibility.

3.BIM technology investment in solution verification and VMU design phase.

4.Multi-level quality review of VMU visual models, model sections, regional tours, etc.

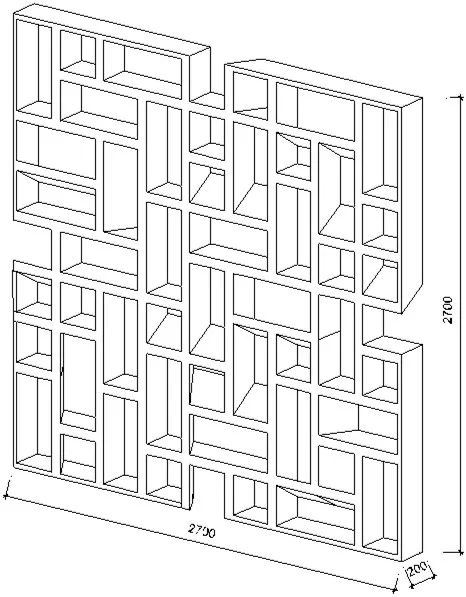

The system scheme is designed as an inner frame-type glass curtain wall and an outer layer of aluminum alloy parametric decorative grate components.

Technical configuration

Viewing area position: 8 (LOW-E) + 12A + 8mm ultra-white tempered insulating glass

Wall position between windows: 6 (LOW-E) + 12A + 6mm ultra-white tempered insulating glass + 2mm aluminum back plate (fluorocarbon spraying)

Inner glass: 12mm single piece of full-color glazed tempered glass

Aluminum component dimensions of the lattice window: 2700mm wide×2700mm high aluminum profile + aluminum plate parameterized customized unit components

Main stress-bearing component: aluminum profile (6063-T6), galvanized steel adapter (Q235)

Podium theater UHPC curtain wall system

Main control factors and design strategies for the implementation of the plan:

Deepening of the facade plan

As the finishing touch next to the main entrance of the shopping mall, and its flexible free-form surface shape must be highlighted. This system is one of the key points of facade performance. It uses BIM technology for multiple modeling to verify the plan, and assists in outputting setting-out size control parameters to finally achieve the architectural effect.

Selection of materials

Exterior decoration UHPC panels, aluminum alloy pendants, galvanized steel keel support structure.

Appearance quality control

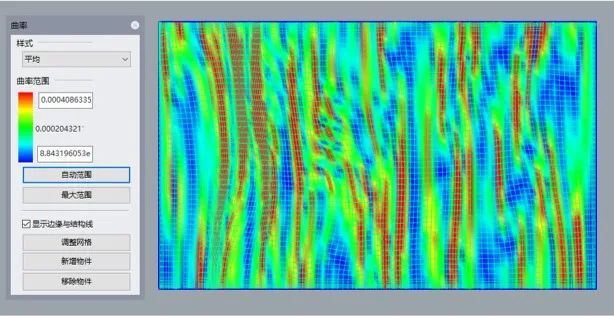

1.Outdoor exterior: Re-carry out parametric modeling and grid modulus control according to the building shape, including curvature optimization analysis; cooperate with the architect and Party A in multiple rounds of reviews of exterior dimensions.

2.Interior: Optimize and streamline the connection structure system.

3.BIM technology investment in solution verification and VMU design phase.

4.Multi-level quality review of VMU visual models, model sections, regional tours, etc.

Plan deepening: In order to achieve visual effects, Rhino digital design was used to analyze the surface of the architectural plan, and important design master control parameters such as the surface curvature and plate division of the system were re-optimized based on the UHPC material production and installation process, and then it was repeated many times with the architect. Confirm the optimization effect. Through the production of VMU visual prototypes, the project further conducts system design verification on material selection, trial production processes, etc. to ensure the implementation of the plan.

Technical configuration

UHPC maximum panel (projection) size: 1350mm wide×2750mm high

Panel configuration: 20mm UHPC customized exterior wall plate

Stress components: hot-dip galvanized steel keel (Q235B), aluminum profile pendant (6063-T6), galvanized steel adapter (Q235B)

Podium ceramic tile curtain wall system

Main control factors and design strategies for the implementation of the plan:

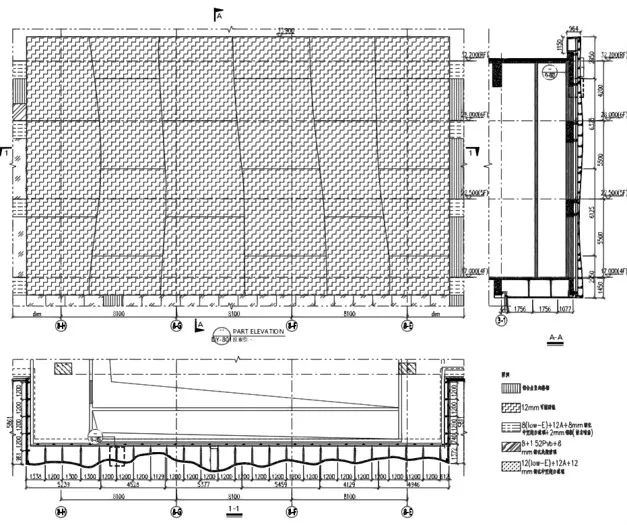

Deepening of the facade plan

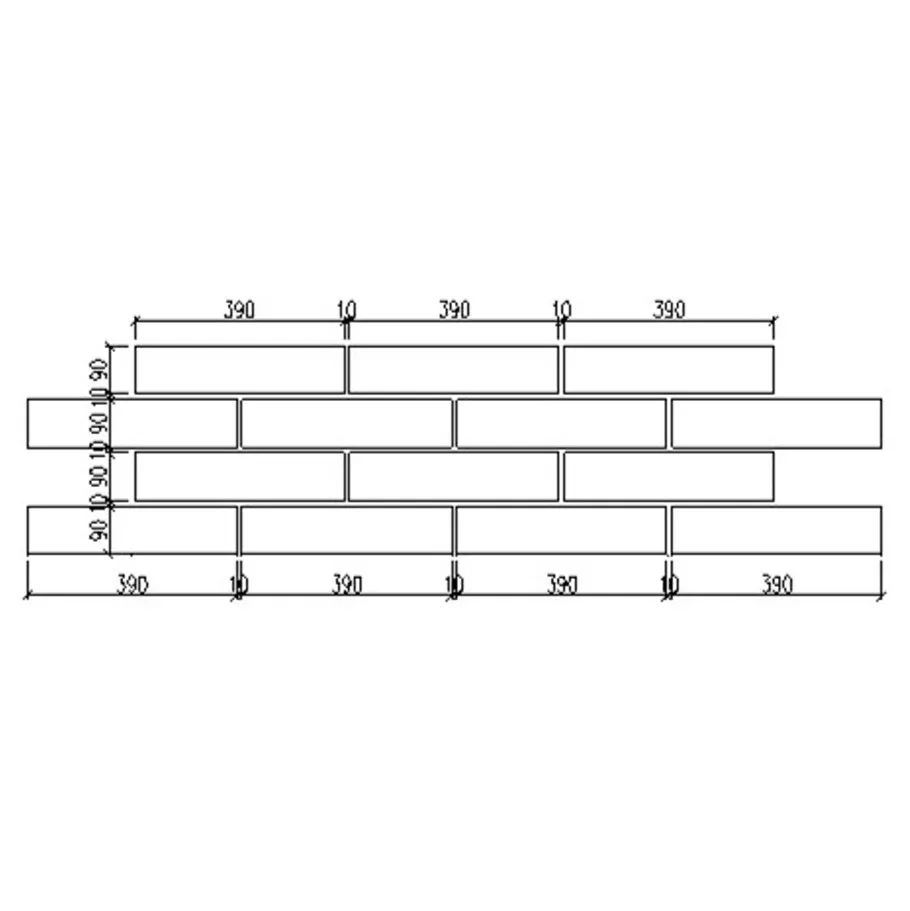

The ceramic brick curtain wall system, which is located on the right side of the main entrance of the mall and under the UHPC curtain wall box of the theater. As the storefront of the main facade along the street, it is also one of the key visual expressions of the facade. The focus is on expressing its rhythmically changing skin texture (staggered seams + concave and convex tiles), and integrating the design with the floodlighting system.

Selection of materials

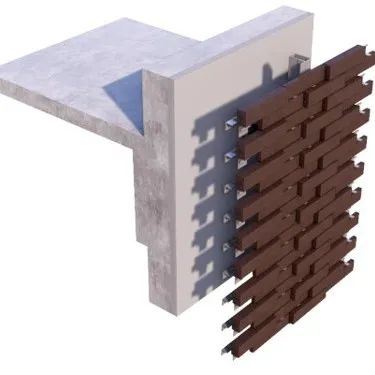

The system plan is to design a frame-type ceramic brick curtain wall, which is supported by galvanized steel keel structure and connected by customized aluminum alloy pendants for ceramic bricks.

Appearance quality control

1.Outdoor exterior: Accurately restore the architectural design intent, use BIM parametric brick arrangement, and accurately realize the building skin texture. The integrated design of ceramic tiles and outdoor floodlighting recessed lamps serves as the finishing touch.

2.Indoor interior: Optimized support steel structure + aluminum alloy pendant support system, multiple adjustment connection mechanisms can ensure the flatness of the ceramic tiles.

3.BIM technology investment in solution verification and VMU design phase.

4. Multi-level quality review of VMU visual models, model sections, regional tours, etc.

The system scheme is designed as a clay brick curtain wall with staggered joints and concave and convex brick arrangement. At the same time, it forms an integrated design with the store door of randomly distributed luminous LED lighting components.

Technical Configuration

Ceramic Tile Plate Size: 390×90×90mm Ceramic Tile & 390×90×60mm Ceramic Tile & 390×90×30mm Ceramic Tile Ceramic Tile Pendant: Aluminum Profile (6063-T6, anodized) Stress-bearing Component: Hot-dip galvanized steel pipe (Q235), galvanized steel adapter (Q235)

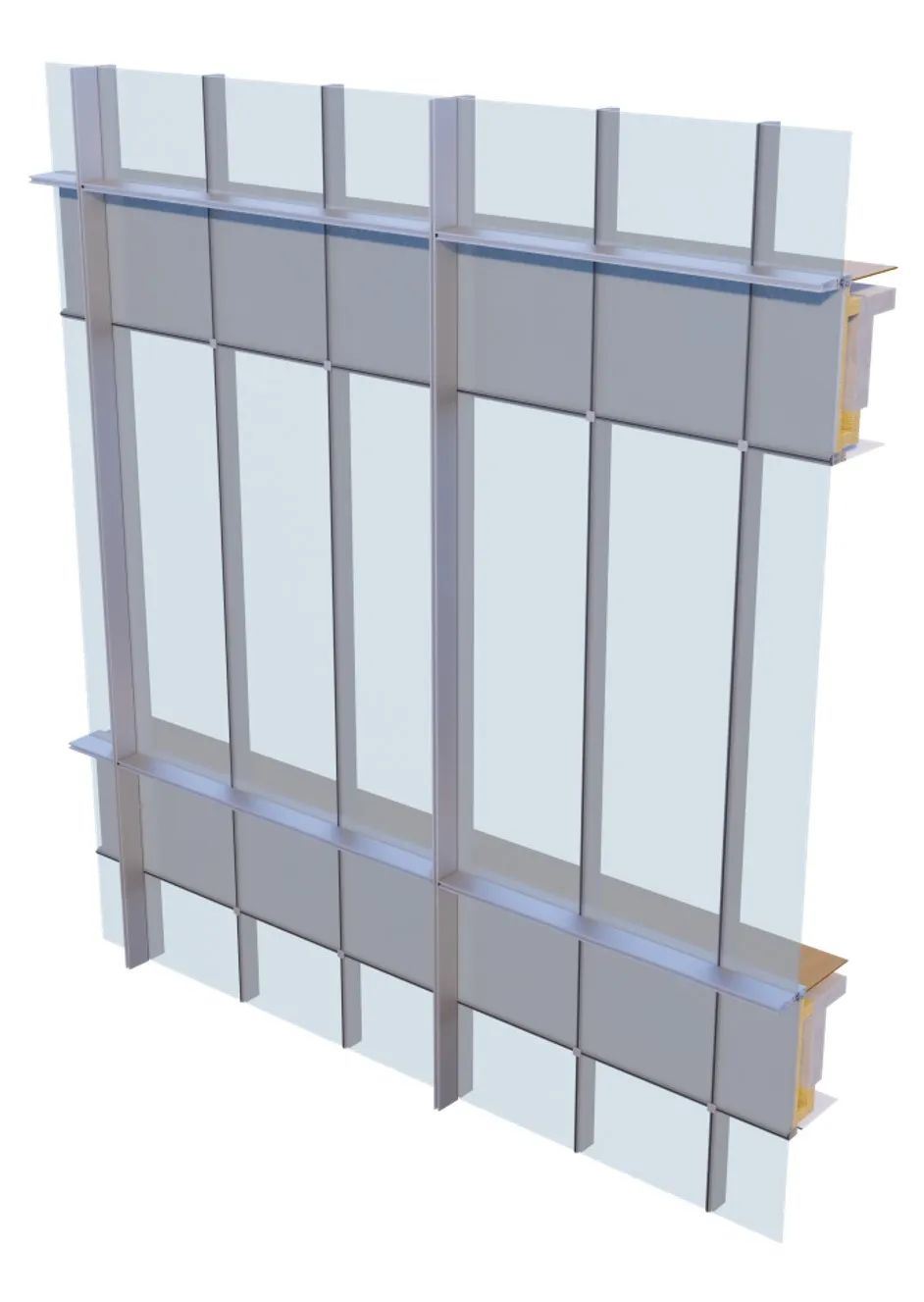

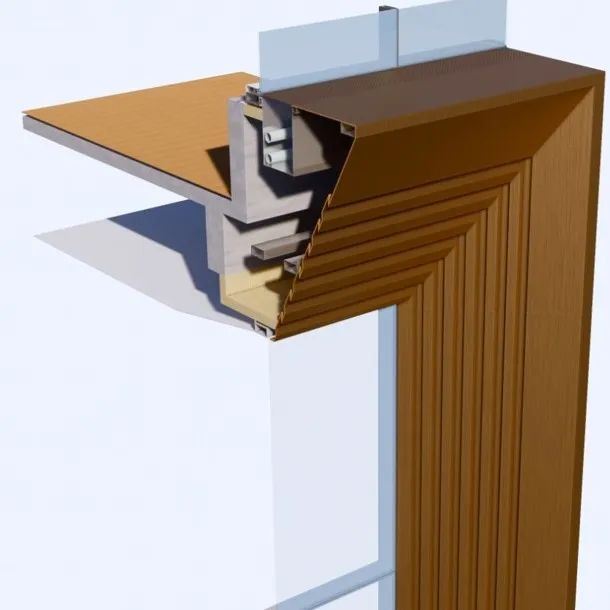

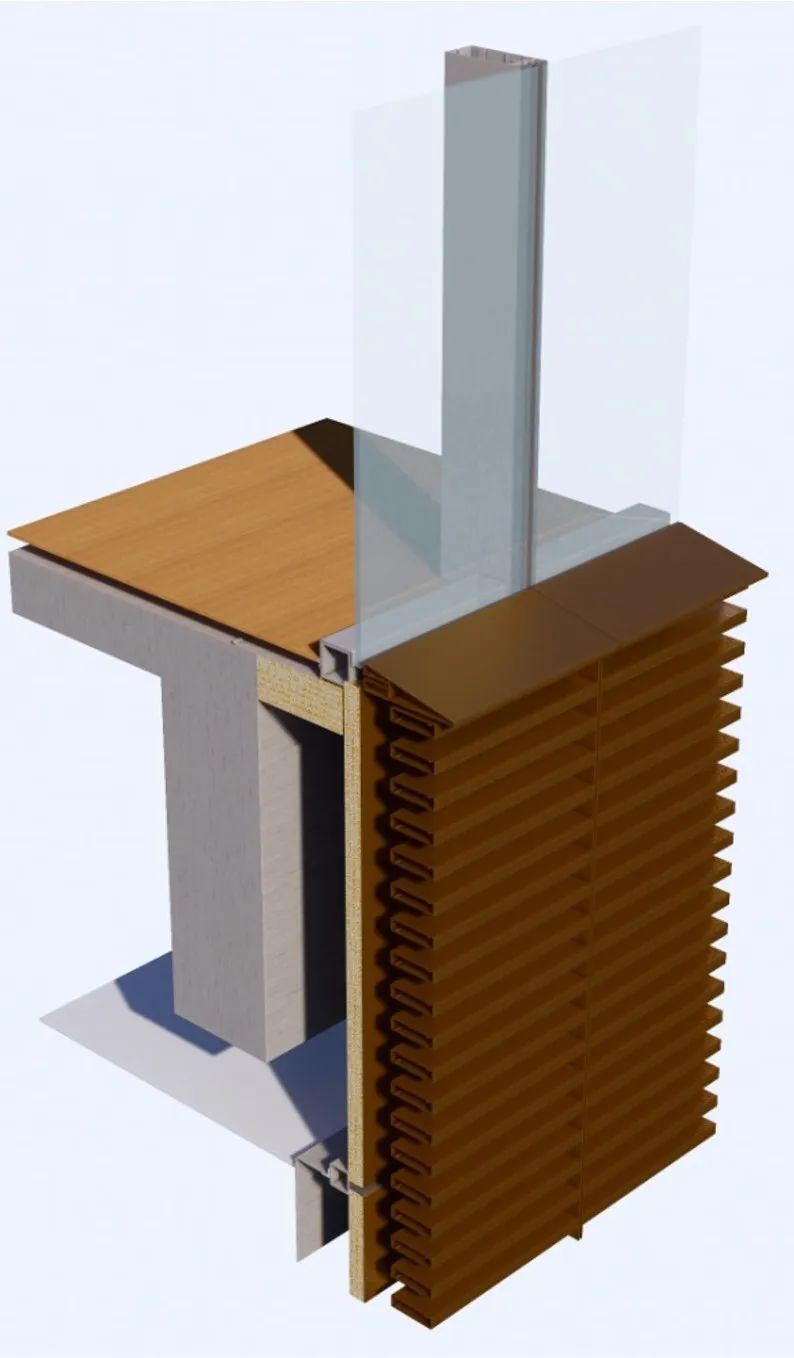

Tower unitized glass curtain wall system with lines

Main control factors and design strategies for project implementation:

Deepening of the facade plan

Coordinate the indoor functional layout of the building, and cooperates with Party A's PM to adjust the unit size and balance the appearance effect and economy through multiple plan comparison and cost-effective analysis (VE value engineering).

Selection of materials

The selection of materials is in line with the preliminary selection of the building plan: the material specifications are further refined based on the design of each curtain wall system; the mature horizontal sliding unit system design is adopted, which is conducive to cost control and refined management of project progress.

Appearance quality control

1.Outdoor exterior: unit processing accuracy and construction and installation errors. The continuity and straightness of exterior decorative lines. Detail control at near-human scale (human sight range), and refined design of edge and edge closures.

2.Indoor surface: The reserved conditions for the intersection between curtain wall design and indoor fine decoration, such as skirting lines, curtain boxes, ceiling openings, etc.. Verify and adjust the indoor visibility effect.

3.BIM technology investment in solution verification and VMU design phase.

4. Multi-level quality review of VMU visual models, model sections, regional tours, etc.

Technical configuration

Standard unit panel size: 1350mm wide×4200mm high

Panel configuration: Viewing area position: 8 (LOW-E) + 12A + 8mm ultra-white tempered insulating glass

Window wall position: 8 ( LOW-E ) + 12A + 8mm ultra-white tempered insulating glass + 2mm aluminum back plate (fluorine carbon spray)

Stress-bearing components: aluminum profile (6063-T6), aluminum pendant (6061-T6)

A kicking foot is set on the aluminum alloy beam on the floor, and the height of the top surface is 40mm from the indoor finished surface elevation. This method can well eliminate the height error between fine decoration and curtain wall closing, and is a widely used method in engineering.

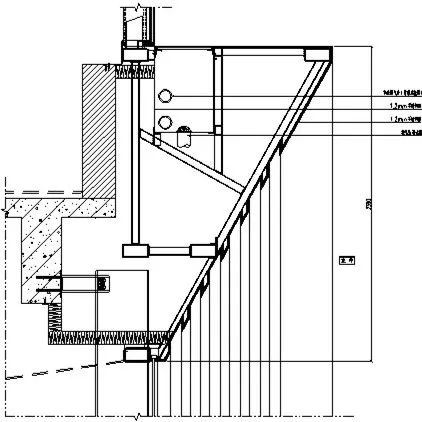

Podium framed glass curtain wall system (with vertical stainless steel lines)

Main control factors and design strategies for the implementation of the plan:

Deepening of the facade plan

As the curtain wall system closest to the main entrance of the entire project, the vertical exterior decorative lines are designed with aluminum alloy exterior sunshade components covered with copper-colored stainless steel finishes to achieve precise control of the building's skin texture and facade aesthetics.

Selection of materials

Frame type glass curtain wall, exterior decoration aluminum alloy panels and components.

Appearance quality control

Outdoor exterior: Strictly follow the architectural plan to control the grid modulus of the curtain wall and decorative lines. Cooperate with the architect to conduct sight-blocking analysis on the specifications and dimensions of the external sunshade decorative components, entry and exit distances, etc.

Interior: The reserved conditions for the intersection of curtain wall design and indoor fine decoration to verify and adjust the indoor visibility effect.

BIM technology investment in solution verification and VMU design phase.

Multi-level quality review of VMU visual models, model sections, regional tours, etc.

Technical configuration

Viewing area position: 8 (LOW-E) + 12A + 8mm ultra-white tempered insulating glass

window wall position: 6 ( LOW-E ) + 12A + 6mm ultra-white tempered insulating glass + 2mm aluminum back plate (fluorocarbon spraying)

Inner glass: 12mm single piece full-color glazed tempered glass

Exterior lattice panel configuration:

2.5mm white aluminum veneer (fluorocarbon spraying, three coatings and two baking), standard specifications: 675mm wide×675mm high

Stress-bearing components: aluminum profile (6063-T6), galvanized steel adapter (Q235)

Podium point buckle cover hidden frame glass curtain wall system (stainless steel door cover)

Main control factors and design strategies for the implementation of the plan:

Deepening of the facade plan

As the main entrance of the shopping mall, its focus is to satisfy the function of guiding people flow and at the same time express the architectural effect of "golden gate".

Selection of materials

The main door curtain wall is made of 12mm ultra-white tempered glass panel, the door cover is made of 1.2mm stainless steel plate (SUS316 brushed), and the galvanized steel keel support structure is used.

Appearance quality control

1.Outdoor exterior: The dense stainless steel door cover design highlights the integrity of the entrance door and the ultimate effect of the decorative lines of the door cover.

2.Interior: Optimize the connection of the supporting steel structure system to meet structural safety while saving materials as much as possible. Use ultra-white high-transparency glass to enhance visibility.

3.BIM technology investment in solution verification and VMU design phase.

4. Multi-level quality review of VMU visual models, model sections, regional tours, etc.

Technical configuration

Viewing area position: 15mm ultra-white tempered single piece glass, the overall visual effect is seamless.

Maximum glass plate size: 2700mm wide×3500mm high

Stress-bearing components: steel pipe (Q235B, fluorocarbon spray), galvanized steel adapter (Q235B)

door cover: 1.2mm stainless steel plate (SUS316 brushed)

Podium frame type double-layer hidden frame glass curtain wall system

System features: Double-layer glass curtain wall of the main store in the podium mall

Maximum glass plate size: 2400mm wide × 6500mm high

Panel configuration: Viewing area position: 15mm ultra-white tempered single-piece glass

Window wall position: 6mm tempered frosted glass Stress-bearing components: steel tube (Q235), aluminum profile (6063-T6), galvanized steel adapter (Q235)

Open frame buckle cover: aluminum profile (6063-T5, fluorocarbon spraying)

Podium aluminum alloy grille system

Technical configuration

Panel configuration: 15 (LOW-E) + 12A + 15mm ultra-white tempered insulating glass

Keel: aluminum profile (6063-T6, fluorocarbon spraying) stainless steel grille (copper color, brushed)

Bottom plate: 3mm aluminum plate (fluorocarbon spraying) , three coats and two bakes)

Podium frame point buckle cover hidden frame glass curtain wall system

Technical configuration:

Visual area position: 12 (LOW-E) + 12A + 12mm ultra-white tempered insulating glass

Wall position between windows: 6 (LOW-E) + 12A + 6mm ultra-white tempered insulating glass + 2mm aluminum back plate (fluorocarbon spraying)

Keel: aluminum alloy profile (6063-T6, fluorocarbon spraying) Point buckle cover: 80mmX80mm stainless steel (SUS316)

Frame-type hidden frame glass curtain wall system for podium shops

Technical configuration

Cornice ceiling: 3mm aluminum plate (anodized)

Visible area position: 12 (LOW-E) + 12A + 12mm ultra-white tempered hollow glass

Keel: aluminum alloy profile (6063-T6, fluorocarbon spraying)

Podium frame type vertically exposed and horizontally hidden glass curtain wall system

Technical configuration

Glass maximum plate size: 1350mm wide × 4250mm high

Viewing area position: 12 (LOW-E) + 12A + 12mm ultra-white tempered insulating glass

Window wall position: 6 ( LOW-E ) + 12A + 6mm ultra-white tempered insulating glass + 2mm aluminum back plate (fluorocarbon spraying)

Stress-bearing component: aluminum profile (6063-T6), galvanized steel adapter (Q235)

Podium frame type exposed frame glass curtain wall system

Technical configuration

Maximum glass plate size: 1350mm wide × 4250mm high

Viewing area position: 12 (LOW-E) + 12A + 12mm ultra-white tempered insulating glass

window wall position: 6 ( LOW-E ) + 12A + 6mm ultra-white tempered insulating glass + 2mm aluminum back plate (fluorocarbon spraying)

Stress-bearing components: aluminum profile (6063-T6), galvanized steel adapter (Q235)