Architectural aesthetics of glass structures

Facade PRO means PROFESSION (professional) and PROGRESS (progress). It selects high-quality innovative curtain wall projects across the country every year, shares new technologies and new materials, promotes the diversified practice and development of building skins, and helps young curtain wall designers grow.

Guests of this issue

Bao Minxi, Deputy Director of Eckersley O'Callaghan

“Understand material properties, ensure accurate and detailed design specifications are obtained, consider curtain wall replacement strategies and durability, focus on node and interface design, and adequate quality control and bench-marking.”

Project 1 in this issue

Marina Bay Sands Apple Store

Making the most of everything: using glass as structure

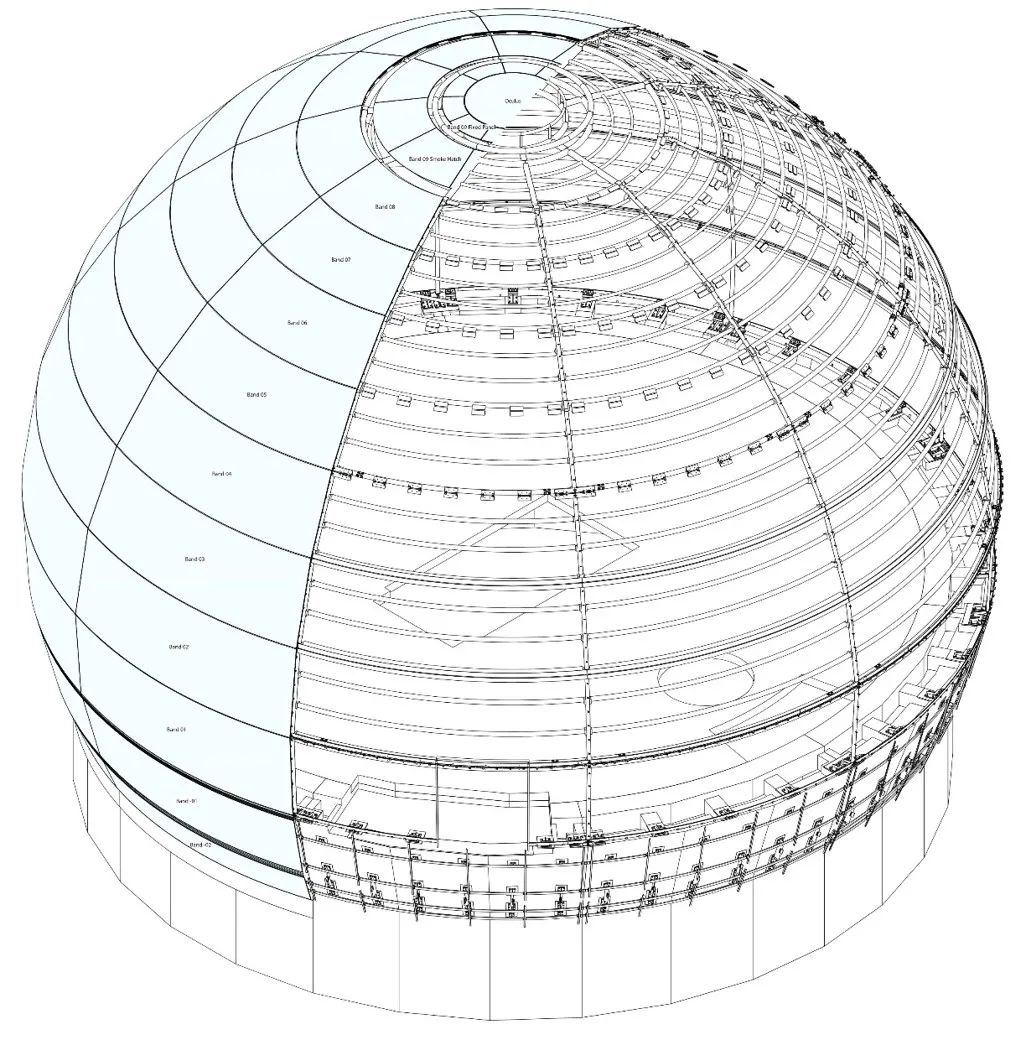

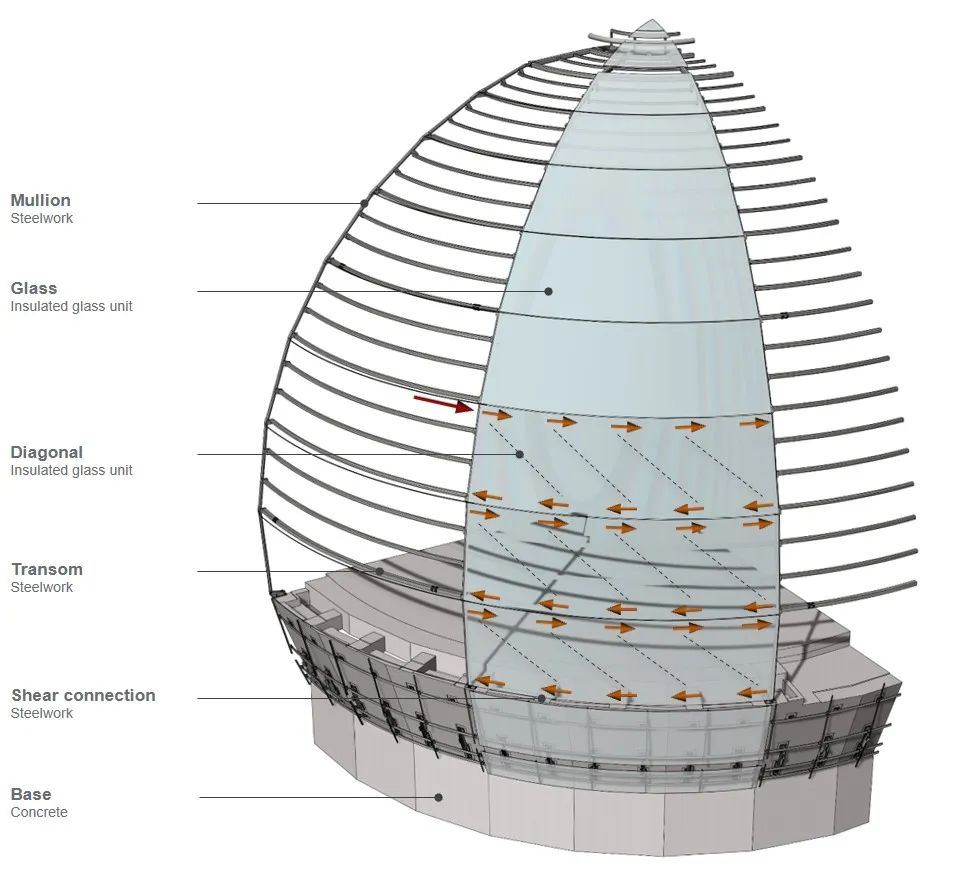

The Marina Bay Sands Apple Store in Singapore is a 30-meter-diameter sphere located on the water. The architects and owners requested that the effect of the project be that of a bubble rising slowly from the water.

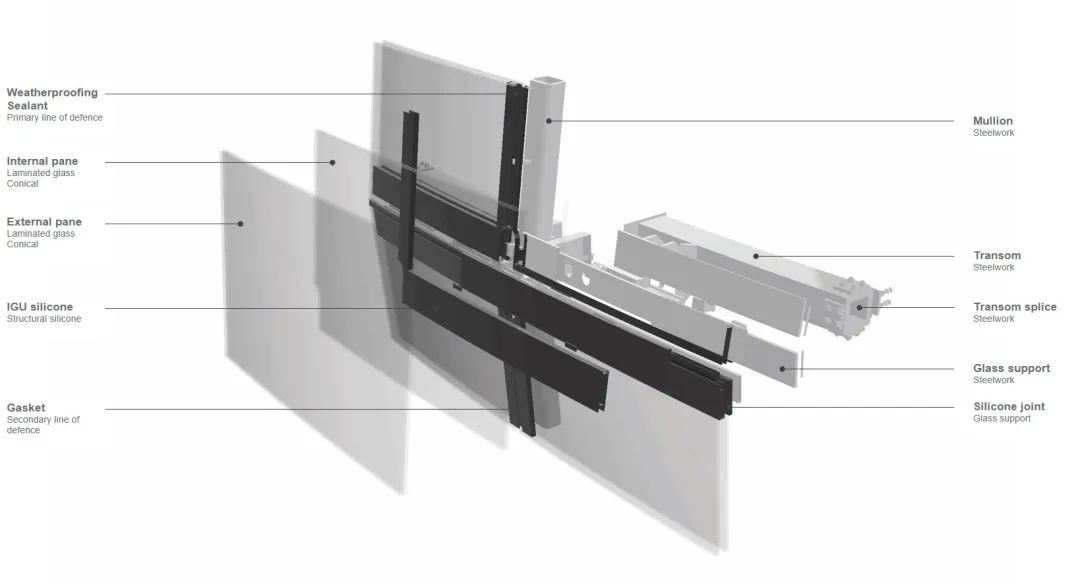

In order to achieve this effect, the outer skin glass is required to use a hidden frame design and cannot have any clamps. At the same time, the transparency of the glass is maximized, the size of the keel is streamlined, and the cover and shield are combined. Therefore, when designing, the principle we follow is to “make the best use of everything”.

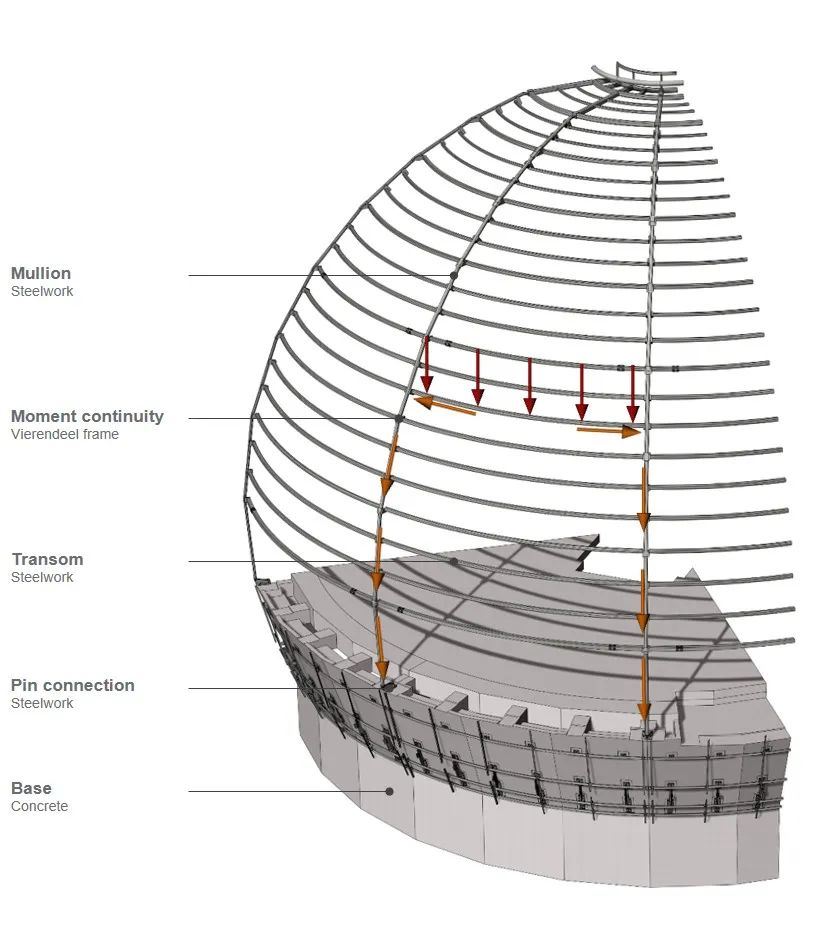

We envision introducing glass as a structural unit into the entire system, similar to the partitions or cross supports of steel components, to provide in-plane lateral support. The biggest challenge of this system is how to accurately control the interaction between the glass plate and the supporting keel behind it.

From the perspective of stress, it is necessary to solve the problem of vertical lateral load. We hope to transfer the lateral load of the glass directly to the keel. First, because the design strength of the glass itself will be reduced when it is subjected to lateral loads. Second, the vertical column of the keel itself is the most direct and effective force transmission path.

In the horizontal direction, we bonded the brackets in advance at the factory. When the glass is transported to the project site, it can be mechanically linked to the keels and beams, and it plays a synergistic role with the keels in the horizontal direction.

The maximum width of the glass plate is 3×9m, which is produced using cold-formed lamination technology. On site, flat glass is used to glue and the shape is fixed in high-pressure fluorine. The advantages of this approach are as followed: First, it saves production costs. Second, it does not affect the coating. Third, the size is flexible.

All the glasses we use are conical in shape, varying the cone radius through different latitudes, and finally fitting into a similar sphere.

Finally, we achieved a very small keel, with ten 22-meter-long columns forming the sphere. The cross-sectional size is 80×120mm. The glass is directly mechanically fixed on the horizontal material through brackets. The glass and plastic are connected with structural glue. Only weather-resistant glue is used between the glass and the glass.

Project 2 in this issue

Taikoo Li , HK

Less wins more: rib-less support for 17 meters of glass

We are responsible for all curtain walls of the project, including the unitized curtain walls of the entire building and the extra-large lobby glass curtain walls. Summarizing the design innovation of the lobby glass curtain wall in four words is "less wins more".

When we first designed the plan, the highest point of the glass curtain wall was about 17 meters, and the owner wanted to make it a large glass without ribs.

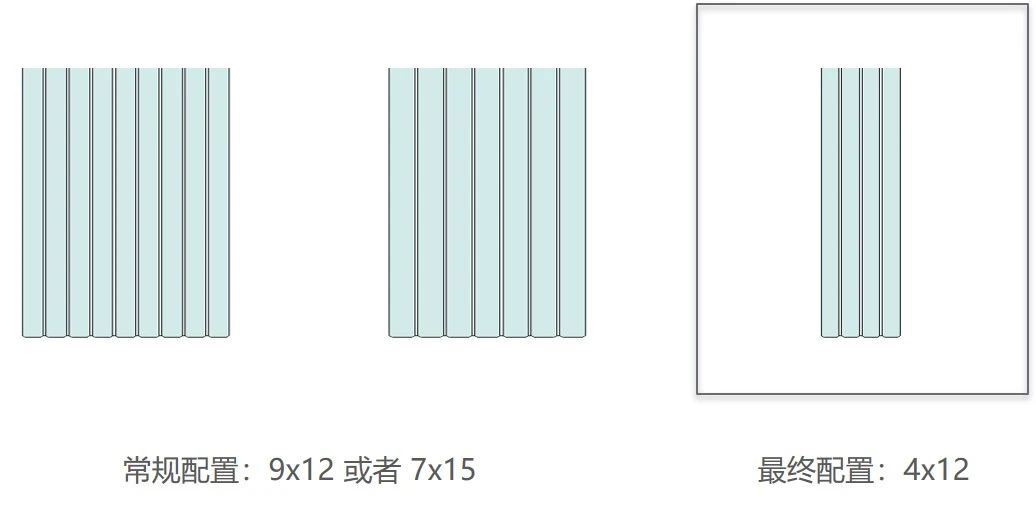

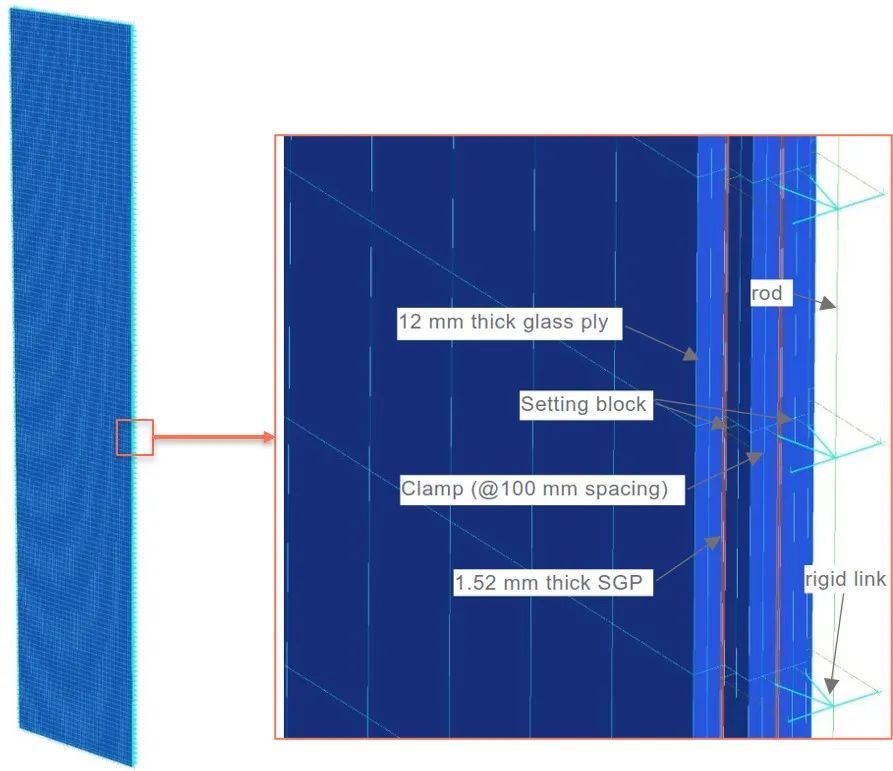

Taking into account the typhoon weather in Hong Kong, the wind pressure at the lobby glass position is about 3.5kPa~4kPa. If conventional methods are used, the glass is equivalent to support at the upper and lower ends, and the thickness of the glass will be very ridiculous, which is basically difficult to produce. At the same time, due to Hong Kong's regulatory requirements, the composite coupling between 100% SGP laminate and glass cannot be fully considered, which will result in a very thick glass configuration. No matter from the perspective of production difficulty, cost or visual effects, it is very unsatisfactory.

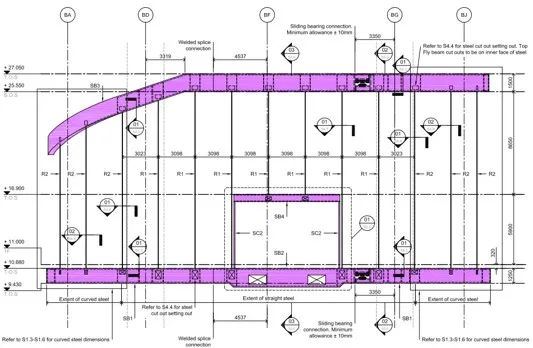

Through innovative design, the final configuration changed to 4×12m, and all glass sizes are the same regardless of height.

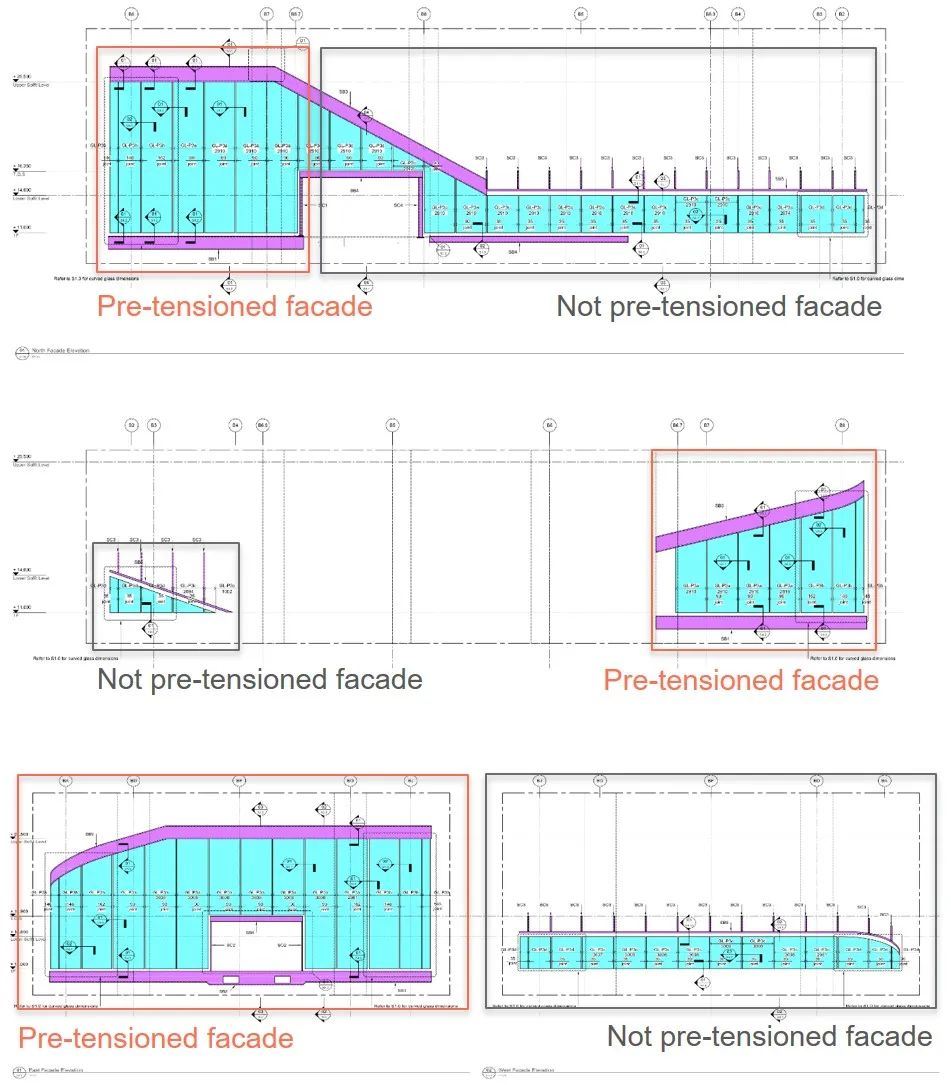

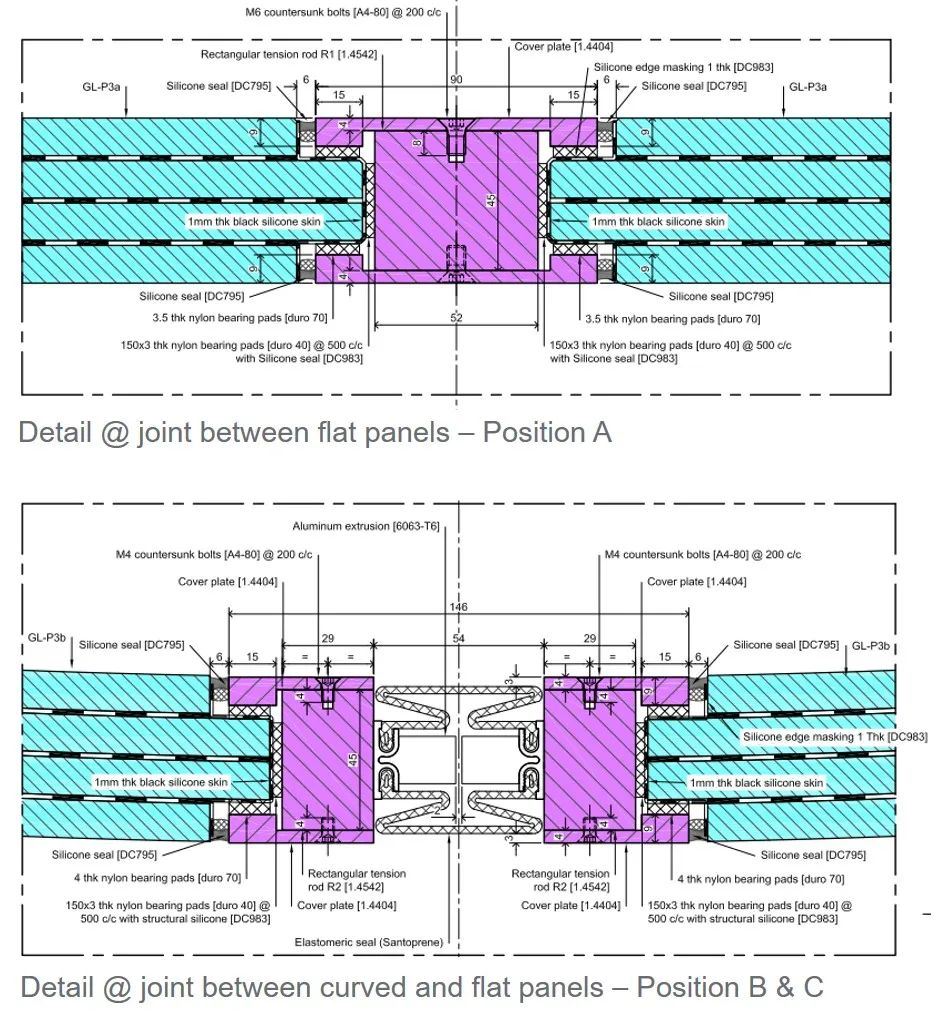

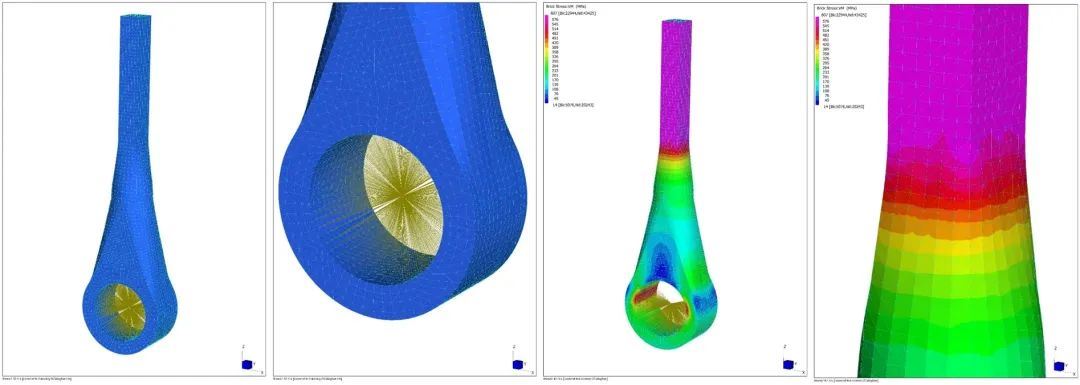

We introduced pre-tensioned stainless steel tie rods to solve the problem of joints between such ultra-high-dimensional glass. After unfolding the entire glass curtain wall, you can see that part of the curtain wall is only over 3 meters high and does not require the use of tie rods. In relatively high places, this needs to be achieved by using tie rods between glass seams.

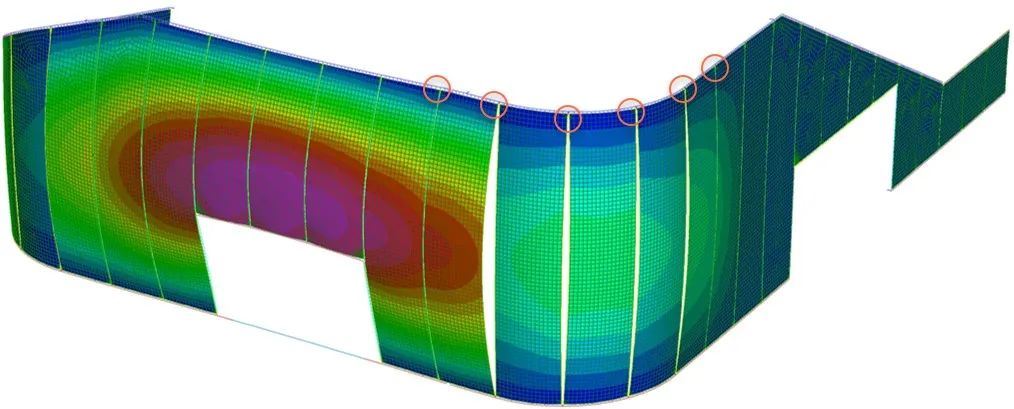

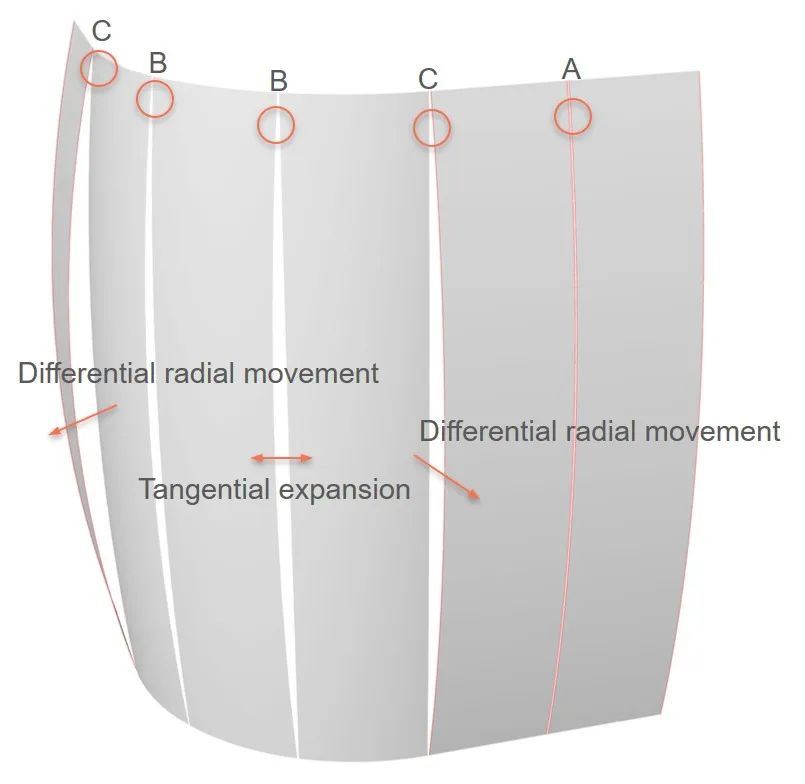

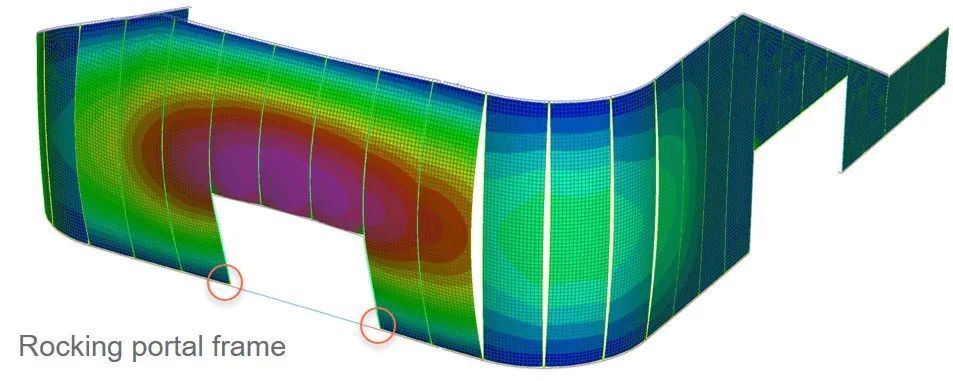

The most challenging part is at the corner. It can be seen from the model that when the glass is supported on the vertical edge by the tie rod, the tie rod itself has a large deflection, so there is a gap between the deflection of the flat glass and the deflection of the corner curved glass. The deformation difference is very large.

The maximum deflection of flat glass can reach 200mm, and each piece of curved glass is bent along the normal direction.

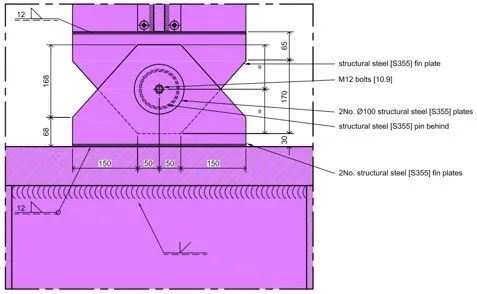

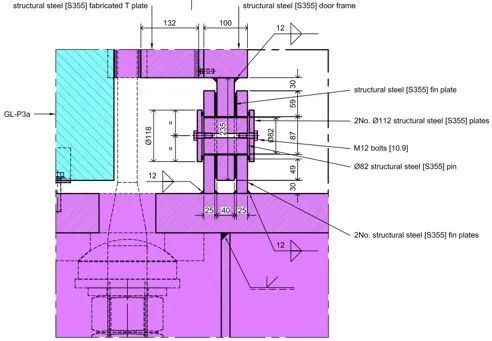

Through a series of initial analyses, we found a design that can place the tie rod in the glass gap while ensuring that it can adapt to displacement changes. The last step is to make an expansion joint at the bottom and tie rods on both sides.

Since the deflection of the curtain wall is very large, the position of the door frame needs to be changed together with the curtain wall, so we made a cut joint under the door frame.

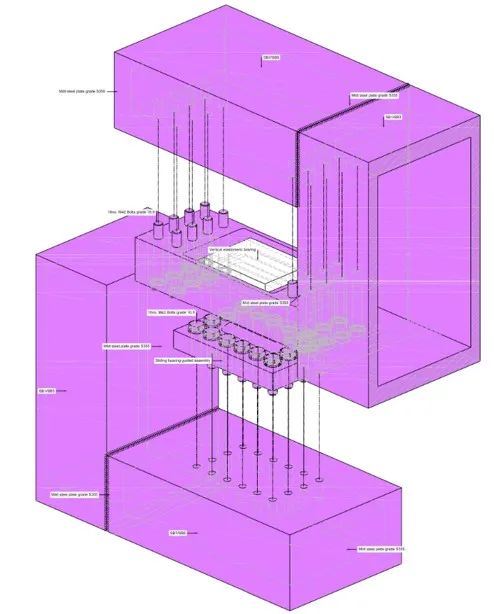

The maximum tensile force of each tie rod can reach 1,500kN, which requires very stiff upper and lower steel beams as support. We need to consolidate the steel beam with the main structure. In this case, the steel beam will become very long, and its internal stress will be very large when it expands thermally.

Therefore, we developed a sliding node to release the thermal stress of the steel beam itself.

This system is a completely innovative system independently developed. We have done a lot of tests, including a full set of PMU wind and rain tests, wind pressure tests, and in-plane displacement tests, to ensure the feasibility of the system.