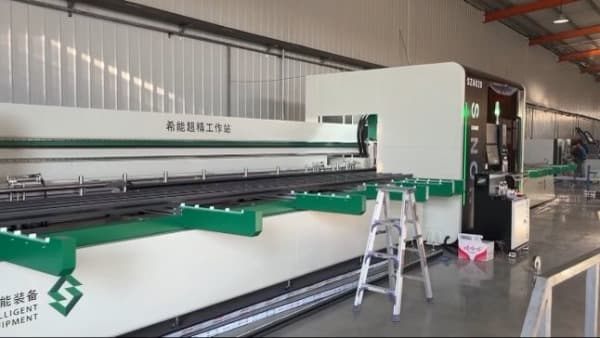

Revolutionizing Window and Door Production: SINON's Intelligent CNC Workstations Deliver Unmatched Efficiency and Energy Savings

Jinan Sinon CNC Machine Co., Ltd. is a leading manufacturer specializing in advanced machinery for producing aluminum, PVC, and uPVC windows and doors in China. With over a decade of expertise, Sinon has developed a comprehensive portfolio of high-performance equipment, including cutting and welding machines, corner cleaning machines, end milling machines, aluminum profile cutting saws, doorframe fabrication solutions, and other specialized systems designed to optimize window and door production.

Committed to continuous innovation, Sinon integrates the latest technologies to enhance and upgrade its machinery, ensuring maximum performance, precision, and reliability. Its extensive product lineup features diverse models tailored to meet evolving market demands, delivering efficient, streamlined, and dependable manufacturing solutions to its global customer base.

Core Advantages: Simplifying Processing through Intelligent Integration

Traditional window and door fabrication often requires complex workflows, with repeated clamping, handling, and sorting of profiles - leading to low productivity and high error rates. Sinon’s latest Intelligent CNC Workstation transforms this process with a revolutionary one-time clamping and fully automated design.

One-Time Clamping, Complete Processing

Once profiles are loaded into the feeder, the system automatically performs all processing tasks, including injection holes, corner code holes, dowel holes, drainage holes, installation holes, lock box holes, mullion grooving, and actuator chamfering. No intermediate handling or sorting is needed, enabling profiles to move directly to assembly, dramatically reducing manual errors and boosting productivity.

Compact Footprint, Operator-Friendly

The workstation features a compact layout that saves valuable workshop space. Its user-friendly interface is easy to learn, even for new operators, minimizing skill barriers and training time.

Faster Processing, Stronger Competitiveness

An intelligent workflow and high level of automation elevate productivity to new heights, whether for small-batch customization or large-scale production - giving manufacturers a powerful competitive advantage.

SINON Intelligent Workstation

High Precision, High Efficiency: Quality You Can Trust

- Imported Control Systems for Superior Accuracy

Sinon’s workstation ensures industry-leading precision and consistent results thanks to top-tier imported control systems and intelligent algorithms.

- One-Time Positioning, Multiple Procedures

Profiles only need to be positioned once to complete cutting, drilling, and milling. The system automatically compensates for length deviations to guarantee the correct location of corner code holes relative to the profile ends.

- Dual-Angle, Dual-Station Design: 80% More Efficient

A dual-angle, dual-station alternating processing mode increases efficiency by up to 80% compared to traditional single-station equipment, significantly shortening production cycles.

- Laser Marking: Precise and Reliable

The integrated dual-laser system guarantees precise positioning of cuts and drill holes, eliminating the risk of human error and further enhancing quality.

SINON Aluminum Cutting Machine

Fully Automated Cyclic Operation: From Raw Material to Finished Product

Sinon’s intelligent workstation is a fully automated system composed of:

- Feeding Conveyor Module

Automatically delivers raw profiles to the processing station, saving manual labor and reducing handling costs.

- Compound Processing Station

Integrates cutting, drilling, milling, and marking, performing all processes in one streamlined system with no manual intervention.

- Discharge Output Module

Automatically transfers finished products to their designated locations, simplifying assembly or packaging.

Thanks to this cyclic operating mode, manufacturers can achieve highly stable, efficient, and continuous production, maximizing output while minimizing downtime.

SINON_CNC DOUBLE HEAD ALUMINUM PROFILE MITER SAW

Intelligent Workstation: Opening a New Chapter in Window and Door Fabrication

With the booming global demand for high-quality windows and doors, manufacturers face both tremendous opportunities and significant challenges. Sinon’s intelligent CNC workstation, with its advanced, efficient, and safe design, solves the pain points of traditional production - while bringing remarkable economic benefits. From dramatically improving productivity and reducing labor costs to enhancing product quality and increasing competitiveness, Sinon’s workstation is your ideal partner.

As a long-standing exhibitor at the Windoor Facade Expo - China’s leading trade fair for window, door, and facade solutions, Sinon will once again showcase its latest intelligent workstation at the 2026 edition, located at Booth 2C04. Industry professionals are welcome to visit on the show floor and explore smarter solutions for window and door production.

The 32nd edition of the Windoor Facade Expo will take place at the Poly World Trade Center in Guangzhou from March 11-13, 2026. Featuring over 500 exhibitors across 70,000 square meters, the event will showcase next-generation window, door, and facade technologies - a must-attend for industry professionals seeking innovation and opportunity.

Don’t miss out - register now to receive the latest updates.

Related News:

Windoor Facade Expo @ Sinon - New Product Release of Aluminum Profile Intelligent Sawing Center